Access to global markets

Our headquarters are strategically located in the city of Monterrey, just a couple of hours away (200 km) from Mexico’s border with the United States of America. The city is recognized as the country’s industrial heart and an important technological development center.

The city’s location and its industrialization facilitate our logistics: Laredo’s proximity in the US and nearby ports on both the Pacific and Atlantic coasts such as Manzanillo, Colima (800 km) and Altamira, Tamaulipas (500 km) enable Viakem to cost-efficiently ship products to the US, Europe, and South America. The US and Brazil are two of the most important end-markets for our services.

Superior Infrastructure

Our strategic location confers Viakem with highly competitive logistics capabilities, including a rail spur. We also benefit from prime infrastructure for utilities such as clean energy, gas, and water essential enablers for growth in our industry. Our newly renovated waste and water management facility ensures compliance with both local and global regulations and is a cornerstone of our sustainability agenda.

At Viakem, innovation is about creating and implementing new ideas or methods that result in positive change or improvement for our customers and our environment. There are two significant enablers for innovation at Viakem: our technical talent and our development infrastructure.

Advanced analytical solutions and innovative product development with versatile assets

QC/Development Lab

Our laboratory is managed by a technical team that includes PhD and Master chemists with dedicated development and analytical technology spaces. They can perform hundreds of experiments per month in a lab area of 168m2, including a dedicated analytical technology space.

Select equipment include:

- 50 gas chromatographers (GC) with automatic injector ports and flame ionization detector (FID) and thermal conductivity detector (TCD)

- 30 liquid chromatographers (HPLC) with automatic injector ports and diode array detector (DAD), multiple wavelength detector (MWD) and variable wavelength detector (VWD)

- Broad inventory of laboratory equipment including Karl Fischer titrators, atomic absorption spectrometer and particle size analyzer among various other tools

- 20 experimentation laboratory hoods

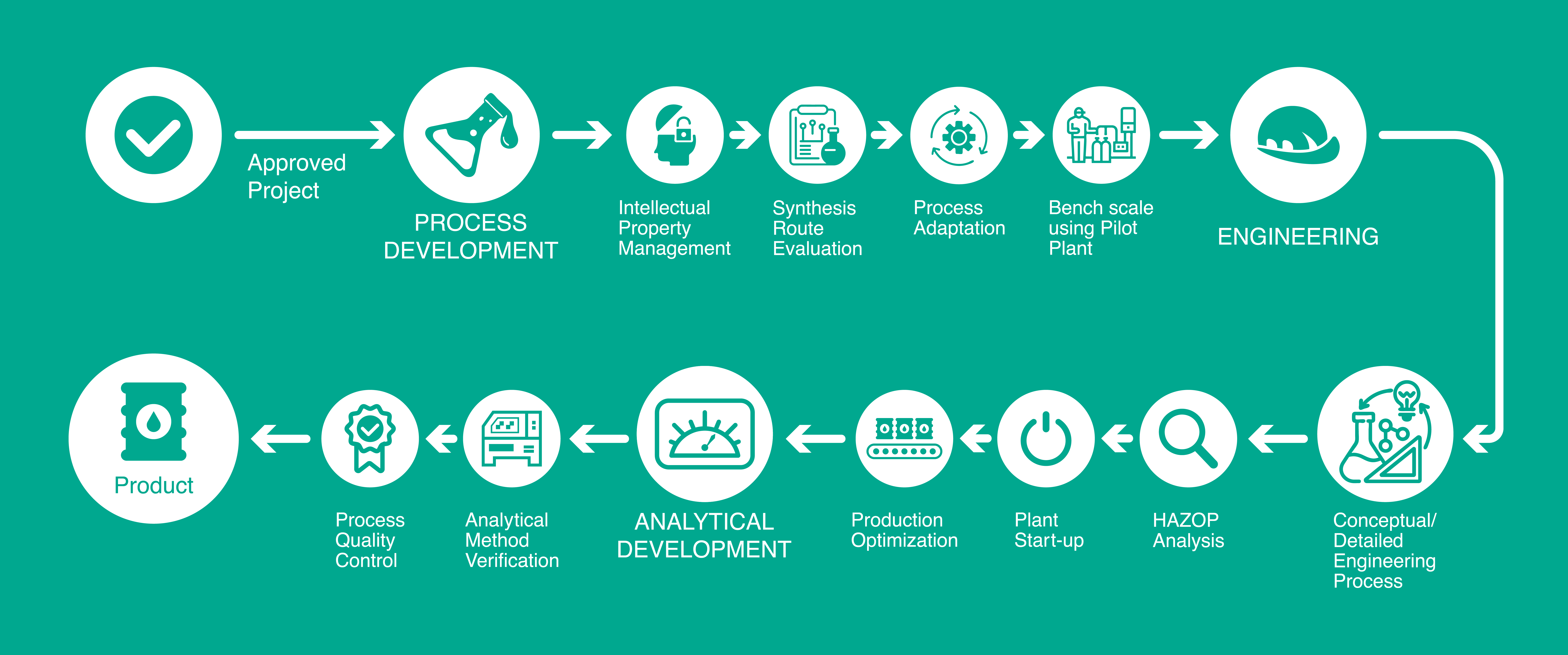

Product Development Flowchart

Pilot Plant Infrastructure

Our pilot plant is equipped with utility services similar to a full-scale production commercial plant. Processes are operated from a centralized control system with safety features, enabling the small-scale production in the plant.

Available utilities and infrastructure include:

- Steam 100 psi / 165°C

- Cooling (chillers, liquid nitrogen) Plant Air

- Thermic fluid

- Temperatures from -50°C to 250°C

- Pressure up to 500 psi and Vacuum pressure up to 0.5mmHg

| Reactors | Equipement | Material | Capacity |

|---|---|---|---|

| Reactor | Glass lined | 10 gal | |

| Reactor | Glass lined | 20 gal | |

| Reactor | Hastelloy | 30 gal | |

| Reactor | Glass lined | 20 gal | |

| Autoclave | SS 316 | 20 gal | |

| Autoclave | Hastelloy | 10 gal |

| Filtering and drying operations | Equipement | Material | Capacity |

|---|---|---|---|

| Nutsche filter | SS 316 | 1 ft2 | |

| Nutsche filter | Hastelloy / Glass lined | 1 ft2 | |

| Dryer | SS 316 | 1 ft3 |

| Separation | Equipement | Material |

|---|---|---|

| Des. Column | Teflon | |

| Des. Column | SS 316 | |

| Des. Column | Hastelloy | |

| Des. Column | Hastelloy |

Month 9-12

Full-scale productions

- Prodcution of customer orders at full capacity

Pilor plant

- Brings more flexibility for process testing (if needed)

- Proof of concept before going to full scale plant product

- Work-in-progress improvements at current products

- Production of samples for registration and validation purposes (e.g. 5 batch analysis)

Month 9-12

Lab

- First step in the develoment process of a new product

- High flexibility to adopt to customer need

It is worth highlighting that our manufacturing infrastructure includes flexible, multipurpose production plants, facilitating expedited new product introductions and enhancing our ability to respond to evolving market needs.

We are a top-tier leader in CDMO (Contract and Development Manufacturing) services for agro fine chemicals and other chemical industry segments, with a special focus on active ingredients and key intermediates.

Our services include:

- A competitive & wide selection of technologies based on multistep synthesis capacity, that enables Viakem to quickly develop or adapt manufacturing systems to meet customer needs

- Dedicated and multipurpose assets offering flexibility and cost competitive solutions to end-customers

- Access to key raw materials from the Americas and Asian markets through a competitive, reliable and agile supplier network ,enabling process backward integration.

At Viakem, we have a diversified, long-standing customer base from a range of industries. Our long-term relationships with core blue-chip customers from niche product markets has been a result of our continuous drive to fulfil and exceed our customers’ needs.

Our ability to innovate is the key ingredient to our service model. Project Development starts at our Technology Department from Technology Packages. Full engineering plans, including all Process Hazard Analysis (PHA) elements and in compliance with HSE standards are then the basis for New Product Developments for our customers.

Our commitment to customer service and highest quality chemical development is our primary driver. To best deliver our services we have ensured that our workforce, facilities, and processes adhere to the highest quality, safety and continuous improvement standards.

We are committed to enhancing our capabilities to meet the ever-evolving demands of global CMDO needs in the agrochemical and specialty chemical industries. Our approach is driven by robust scientific research and development, all while adhering to best practices.

We are currently serving customers in the agrochemicals, personal care, and electronic chemicals, specialty polymers, specialty construction chemicals, among others.

These are our specialized and competitive spectrum of chemical capabilities:

| Chemistry core competencies | Raw material examples |

| Chlorinations and Halogenation | Cl2, Br2 |

| Coupling reactions | |

| Cyanation | NaCN, HCN |

| Thiolation | Mercaptans |

| Grignard reaction | Halogenated materials, Mg0 |

| Oxidation | |

| Hydrogenation | H2, Hydrazine hydrate |

| Methylations | Dimethyl sulfate |

| Nitrations | High concentration HNO3 |

Extensive list of Viakem’s chemical capabilities

| Acetylation Reactions |

| Aldol Condensation |

| Amidation |

| Amination |

| Ammonolysis |

| Halogenation |

| Chlorination Reactions |

| (Cl2, SOCl2, SO2Cl2, POCl3) |

| Bromination Reactions |

| Catalytic Dehydrogenation (Pd/C) |

| Catalytic Reduction (Pd/C) |

| Condensation Reactions |

| Coupling Reactions (Kumada, Suzuki) |

| Cyanation |

| Cyclization |

| Diazotization |

| Dimethyl Sulphate [DMS] Methylations |

| Esterification |

| Friedel-Crafts Reaction |

| Grignard Reaction |

| Hydrazine Chemistry |

| Hydrogenation Reactions |

| Hydrolysis |

| Hydroxylation |

| Polymerization Reactions |

| Skraup Synthesis |

| Strecker Amino Acid Synthesis |

| Sulfonation |

Key technical capabilities offered at Viakem

| Technical capability | Viakem’s differentiator |

| New product registration support | Quick batch production at multipurpose or pilot plants |

| Scale-up and plant design from laboratory data | Agile and efficient design and construction of commercial scale manufacturing trains |

| Supply chain security | CTPAT compliant processes |

| Commercial product launch capability | Flexibility to develop product life along with customer (from new product introduction to maturity) |

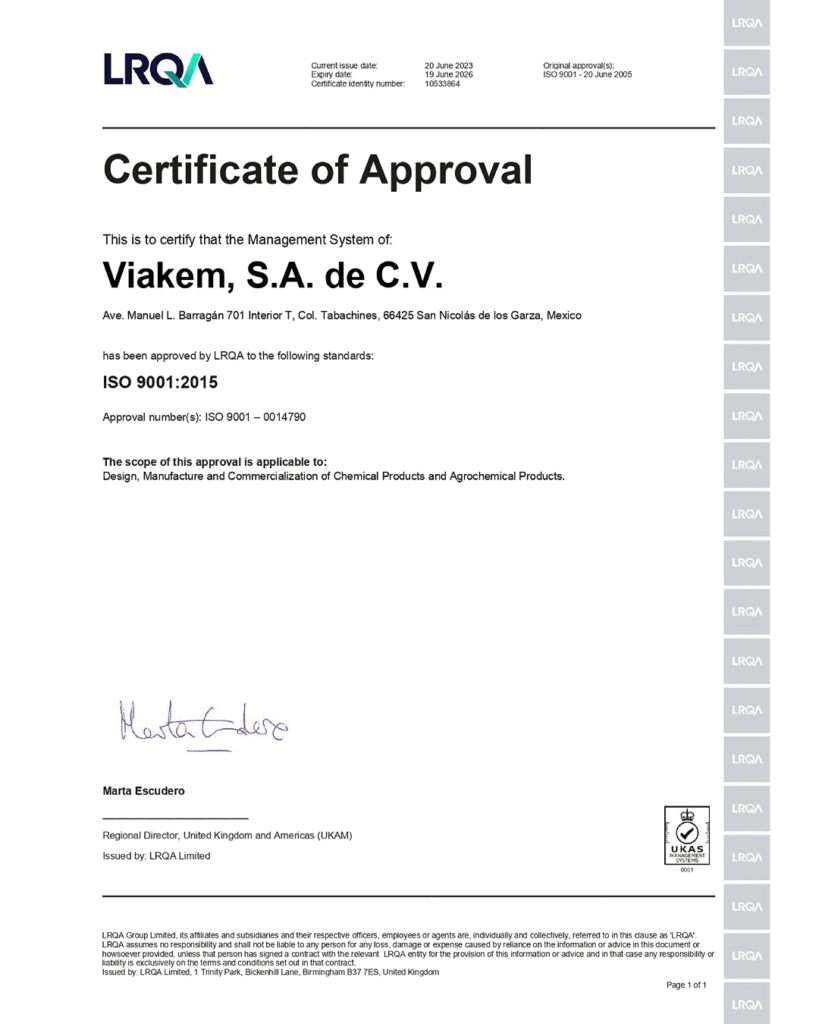

ISO-9001:2015

CTPAT

Responsible Care

Top Companies

ISO-9001:2015

Our Total Quality Administration System (SACaT) establishes guidelines that govern the company’s operation of internal processes, which promote customer satisfaction and continuous improvement.

VIAKEM’s quality assurance system meets the requirements specified in the world’s most widely recognized standard: ISO-9001:2015 enabling the company to offer its customers a quality warranty supported by the International Standards Organization.

ISO-9001:2015 CERTIFICATION NUMBER MQA 10533863 GRANTED BY LRQA REGISTER QUALITY ASSURANCE LIMITED

CTPAT

As a Validated CTPAT (Customs-Trade Partnership Against Terrorism) organization, we are committed to maintaining the highest standards of security in our supply chain. This certification demonstrates our dedication to preventing illegal activities, ensuring the safe and efficient movement of goods, and complying with international trade regulations. Our security protocols are continuously reviewed and enhanced to meet the requirements set by U.S. Customs and Border Protection, fostering trust and reliability with our partners and clients worldwide.

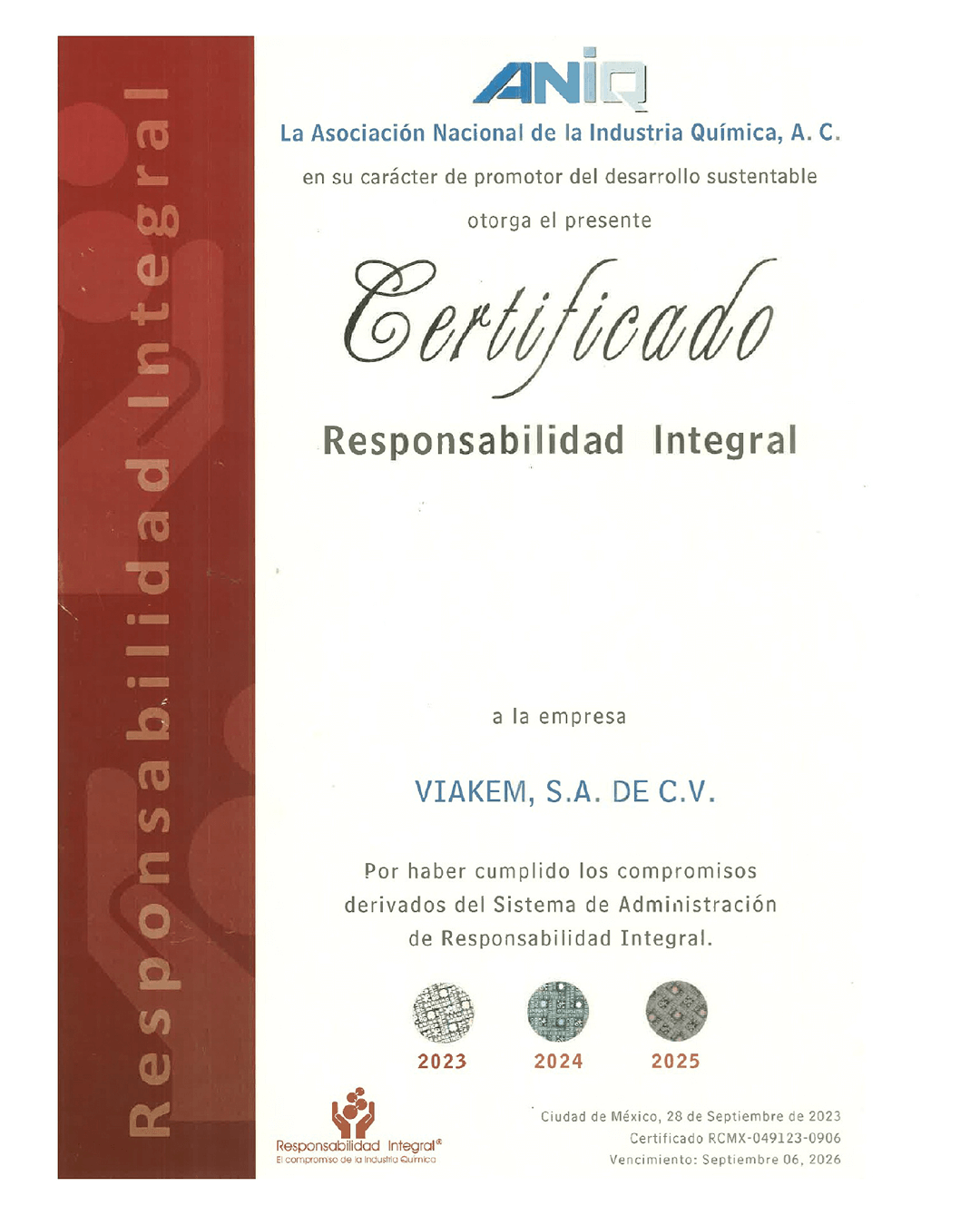

Responsible Care

The members of the National Chemical Industry Association in Mexico ( ANIQ ) are committed to safety and sustainability in the communities where we operate and in the products we manufacture. Through implementation of Responsible Care, our members demonstrate their commitment the health and safety of their employees, the communities in which they operate and the environment as a whole.

Participation in Responsible Care is encouraged for all ANIQ members, all of which have made CEO-level commitments to the program, including:

- Signing the Responsible Care Guiding Principles

- Tracking and transparently reporting company performance on environmental, health, safety and security metrics

- Undergoing third-party audit and certification to Responsible Care Management System

- Implementing the Product Safety, Process Safety and Security Codes

Top Companies

The members of the National Chemical Industry Association in Mexico ( ANIQ ) are committed to safety and sustainability in the communities where we operate and in the products we manufacture. Through implementation of Responsible Care, our members demonstrate their commitment the health and safety of their employees, the communities in which they operate and the environment as a whole.

Participation in Responsible Care is encouraged for all ANIQ members, all of which have made CEO-level commitments to the program, including:

- Signing the Responsible Care Guiding Principles

- Tracking and transparently reporting company performance on environmental, health, safety and security metrics

- Undergoing third-party audit and certification to Responsible Care Management System

- Implementing the Product Safety, Process Safety and Security Codes

Ideal location to approach USA & Brazil markets

Long term stability

Multisteps synthesis capability in one site

Continuous improvement and optimization of processes

Qualified workforce (manpower)

Wide experience handling difficult materials

Environmentally conscious

In-house Project management and implementation

Internationally certified operations

Competitive cost structure